NTM SSQ II MultiPro Roof and Wall Panel Machine

Call for Price

Commercial & Residential Multi-Profile Roof Panel Machine

- 16 quick-change profiles for one machine

- The SSQ II is our latest iteration of the best-selling, most advanced, accurate, and user-friendly multi-profile machine

- Available with angle cutting & notching functions

- Change tooling in 45 minutes or LESS with one person and one wrench

- Contractors all over the world trust this machine with their business

- Offered with the industry’s best warranty

- Available with manual control or the option to upgrade to the UNIQ® Automatic Control System

- Description

- Specifications

- Resources

- Profiles

- Reviews (0)

Description

Standard Features

- Polyurethane Drive Rollers

- Roller System with Shear Dies

- Hydraulic Drive & Shear

- Powder-Coated Frame

- Aluminum Covers

- Welded Tubular Steel Frame

- Push Button RUN/JOG Controls at Entry & Exit Ends

- Power Interruption Safety Circuit

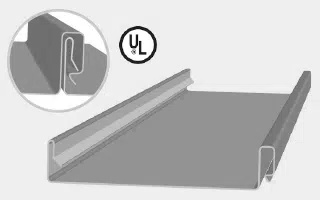

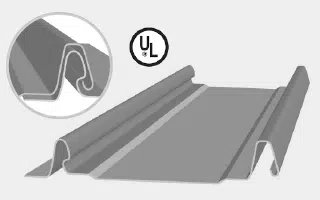

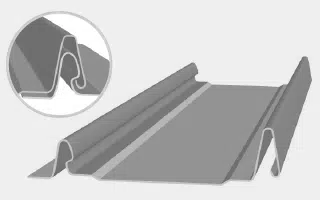

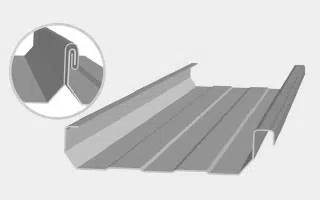

- UL Rated Panels (Must Be Certified by UL for Recognition)

- Industry’s Best Warranty

- Choice of: Quick-ChangeTM Profile Roller System

- Choice of: Quick-ChangeTM Power-Pack (Gas or Electric)

- Choice of: One Pair of Bead, Pencil, Striation or V-Rib Rollers

Warranty:

New Tech Machinery provides a limited three-year part and NTM in-house labor warranty.

Patents:

U.S. PATENT NO. 6,772,616

Profile Disclaimer:

New Tech Machinery provides no warranty (finish, substrate or weather tight) in relation to the metal roofing systems the machines form. Should a warranty be required, users should consult with metal roof manufacturer or coil supplier prior to contracting on work. It is the sole responsibility of the installer and/or metal panel manufacturer to ensure that the roof system meets all engineering and local building codes.

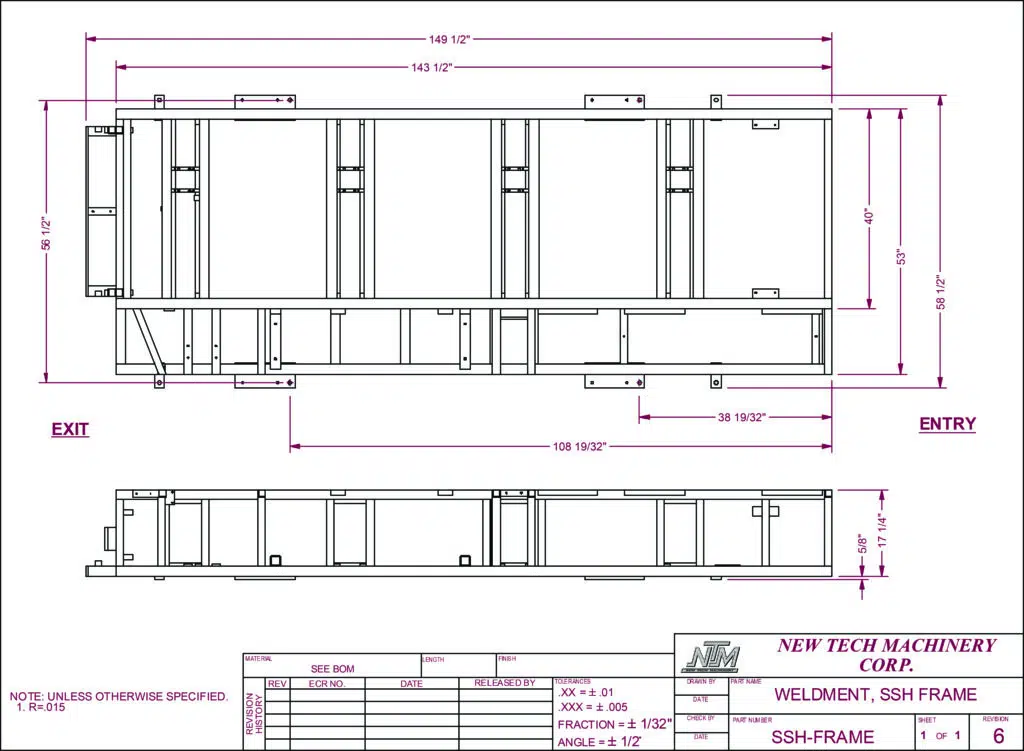

SSQ II Panel Machines:

- Length: 14’4” (4.4m) without Angled Slitter, 15’4” (4.7m) with Angled Slitter

- Width: 5′ 2″ (1.57m)

- Height with Over Head Rack: 4’ 3” (1.3m)

- Height without Over Head Rack: 2’ 6″ (0.8m)

- Weight (Base Machine with Roller Set, Power Pack, and Rib Rollers) 2,830 lbs. (1,280 kg)

SSQ II On Trailer:

- Length: 18’11” (5.8m)

- Width: 7’2½” (2.2m)

- Height with Reel: 6’3” (1.9m)

- Weight of Machine & Trailer (including Roller Set, Power Pack, and Rib Rollers): 5,090 lbs (2,300 kg)

Shear:

- Hydraulically Powered, Infinitely Adjustable, Hardened Tool Steel Blades & Shear Dies

- Panel Recognition Safety System

Drive:

- 16 Polyurethane Drive Rollers, Hydraulically Driven via Chain, Sprocket & Gear

Speed

- Up to 75 ft./min (23m/min) Approx.

SSQ II Add-On Option Weights

- Trailer: 2,260 lbs. (1,020 kg)

- Overhead Reel Rack: 336 lbs. (152 kg)

- Expandable Arbor, each: 80 lbs. (36 kg)

- 10-foot Run-out Table, each: 62 lbs. (28 kg)

- Perforator: 150 lbs. (68 kg)

- Notching System: 220 lbs. (100 kg)

- Angled Slitter: 250 lbs. (113 kg)

- PVC Strippable Film Applicator: 60 lbs. (27 kg)

Materials Formed:

- Painted Steel: 28 ga. to 22 ga. (0.4mm to 0.8mm) (painted, Galvalume, coated galvanized)

- 50 ksi maximum for 24 to 22 ga.

- 50 ksi recommended, 80 ksi acceptable with adjustments for 28 ga. to 26 ga.

- Painted Aluminum: .027” to .040” (0.7mm to 1.0mm)

- Copper: 16 oz. to 20 oz. 3/4 Hard (0.5mm to 0.7mm)

- Note: Notching not recommended with copper.

- Terne Coat Stainless: 26 ga. (0.5mm) Note: Notching not recommended with terne coat.

Coil Widths:

- 15” to 30” (381mm to 762mm)

Maximum Coil Diameter

- 32” (812mm) with the Overhead Reel Rack 45” (1,143mm) with the Free Standing Decoiler

Finished Panel Widths:

- 12” to 24” (305mm to 610mm) – Note: Variable Depending on Panel Profile

Power Options

- 7.5 HP, 220V, 60 Hz, 3PH, 18 amps

- 5 HP, 220V, 60 Hz, 1PH, 20 amps

- Gas Power (16 HP Briggs & Stratton Engine)

- 5 HP, 380V, 50 Hz, 3PH, 8 amps (overseas use)

- 7.5 HP, 460V, 60 Hz, 3PH, 9 amps

- 5 HP, 220V, 50 Hz, 1PH, 21 amp

Manuals:

- SSQ II Roof Panel Machine Manual

- SSQ Roof Panel Machine with AMS Controller Manual

- SSQ Roof Panel Machine with AMS Controller Manual (Spanish)

- SSQ Roof Panel Machine with PLC Controller Manual

- SSQ Roof Panel Machine with PLC Controller Manual (Spanish)

Literature:

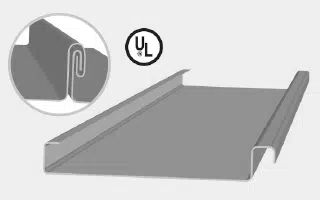

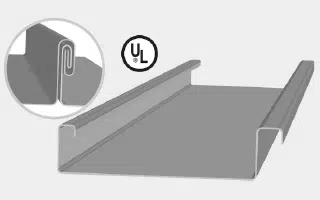

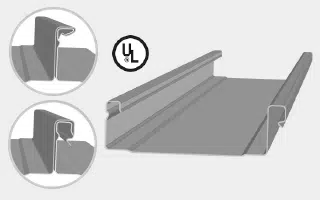

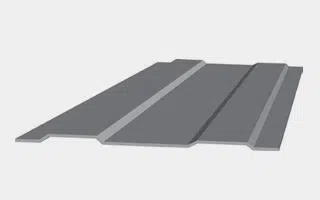

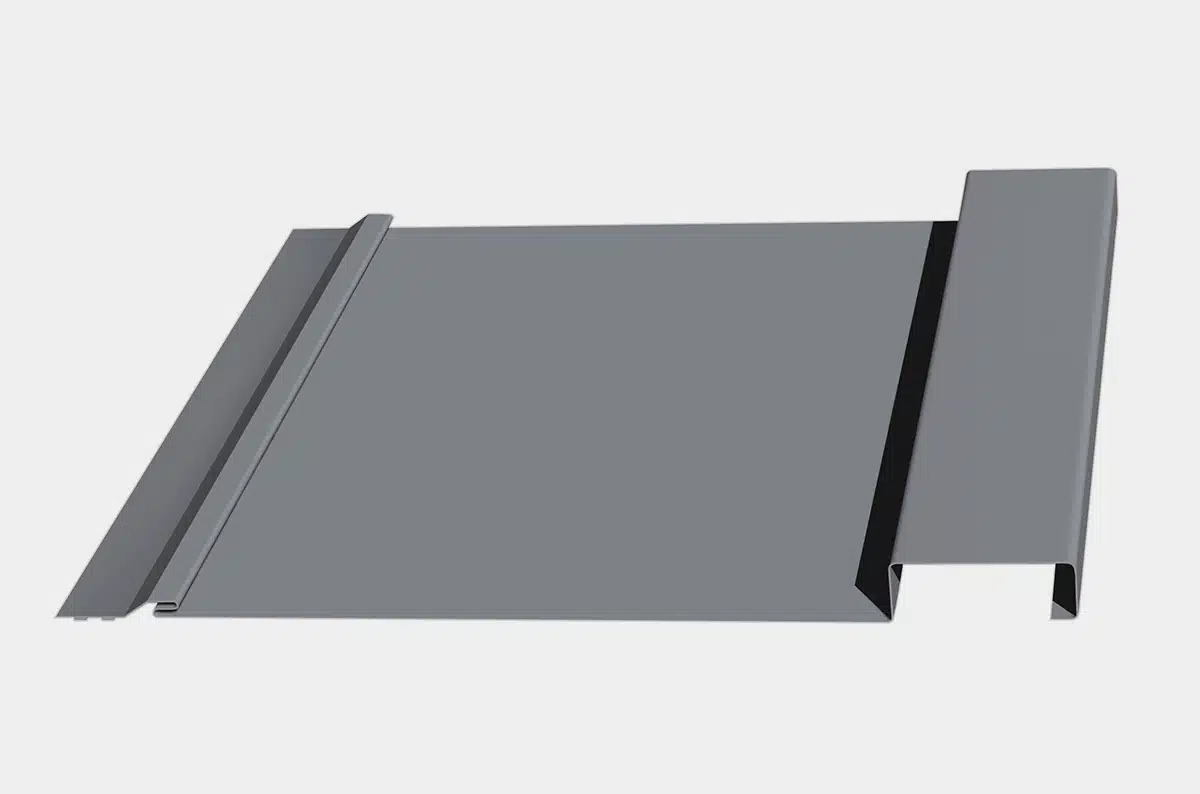

SS100 – 1″ Mechanical Seam

SS150 – 1.5″ Mechanical Seam

SSQ200 – 2″ Mechanical Seam

SSQ210A – 2″ ARMCO Mechanical Seam

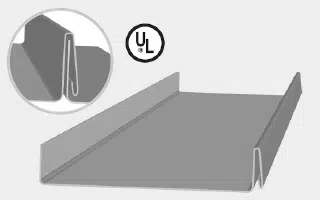

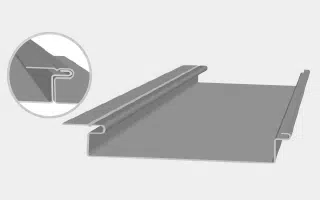

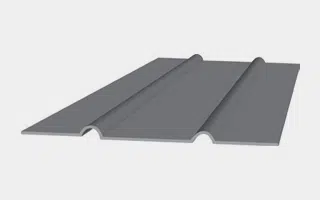

SS450 – 1.5″ Snap-Lock

SS450SL – 1.5″ Snap-Lock

SSQ550 – 1.5″ Snap-Lock

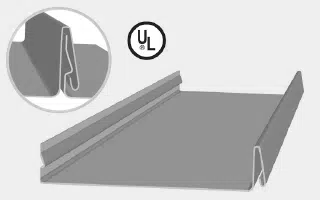

SSQ675 – 1.75″ Snap-Lock

FF100 – 1″ Snap-Lock With Slotted Flange

FF150 – 1.5″ Snap-Lock With Slotted Flange

TRQ250 – 2.5″ Mechanical Seam Trapezoid

SSQ275 – 2″ Snap-Lock/Mechanically Seamed Proprietary Profile

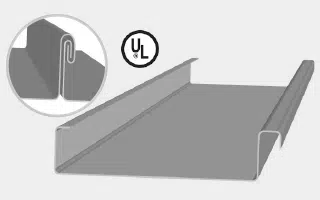

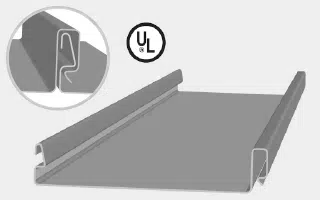

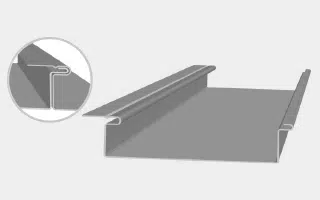

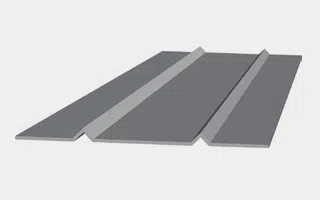

FWQ100 – 1″ Flush Wall/Soffit/Underdeck Panel With Adjustable Reveal

FWQ150 – 1.5″ Flush Wall/Soffit/Underdeck Panel With Adjustable Reveal

Clip Relief

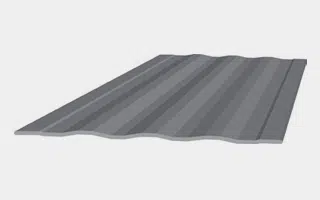

Bead Ribs (Standard or Wide)

Pencil Ribs (Small or Large)

V-Ribs (Small or Large)

Striation Ribs

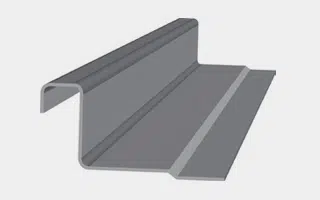

T-Panel

BB750 Profile – Board and Batten

SS100 – 1″ Mechanical Seam

SS100 – 1″ Mechanical Seam SS150 – 1.5″ Mechanical Seam

SS150 – 1.5″ Mechanical Seam SSQ200 – 2″ Mechanical Seam

SSQ200 – 2″ Mechanical Seam SSQ210A – 2″ ARMCO Mechanical Seam

SSQ210A – 2″ ARMCO Mechanical Seam SS450 – 1.5″ Snap-Lock

SS450 – 1.5″ Snap-Lock SS450SL – 1.5″ Snap-Lock

SS450SL – 1.5″ Snap-Lock SSQ550 – 1.5″ Snap-Lock

SSQ550 – 1.5″ Snap-Lock SSQ675 – 1.75″ Snap-Lock

SSQ675 – 1.75″ Snap-Lock FF100 – 1″ Snap-Lock With Slotted Flange

FF100 – 1″ Snap-Lock With Slotted Flange FF150 – 1.5″ Snap-Lock With Slotted Flange

FF150 – 1.5″ Snap-Lock With Slotted Flange TRQ250 – 2.5″ Mechanical Seam Trapezoid

TRQ250 – 2.5″ Mechanical Seam Trapezoid SSQ275 – 2″ Snap-Lock/Mechanically Seamed Proprietary Profile

SSQ275 – 2″ Snap-Lock/Mechanically Seamed Proprietary Profile FWQ100 – 1″ Flush Wall/Soffit/Underdeck Panel With Adjustable Reveal

FWQ100 – 1″ Flush Wall/Soffit/Underdeck Panel With Adjustable Reveal FWQ150 – 1.5″ Flush Wall/Soffit/Underdeck Panel With Adjustable Reveal

FWQ150 – 1.5″ Flush Wall/Soffit/Underdeck Panel With Adjustable Reveal Clip Relief

Clip Relief Bead Ribs (Standard or Wide)

Bead Ribs (Standard or Wide) Pencil Ribs (Small or Large)

Pencil Ribs (Small or Large) V-Ribs (Small or Large)

V-Ribs (Small or Large) Striation Ribs

Striation Ribs T-Panel

T-Panel BB750 Profile – Board and Batten

BB750 Profile – Board and Batten

Reviews

There are no reviews yet.