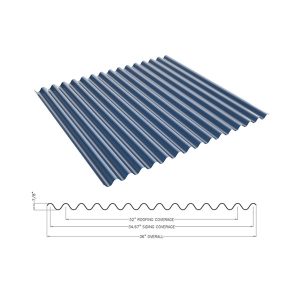

1/2 Exposed Fastener Corrugate Panel

Exposed fasteners can be seen on top of the panel after the installation is completed, providing a classy look to your metal roof. The hardware is directly secured through the face of the panel with the underlying structure. As the panels overlap one-another, the exposed fastener is driven through both panels, its head remains visible on the outside of the building. Corrugated or PBR panels are examples of fastening metal panels. Exposed fastener wall panels are becoming increasingly popular in commercial-style buildings, and are also used in many domestic projects that want to give a classy look to their accommodation.

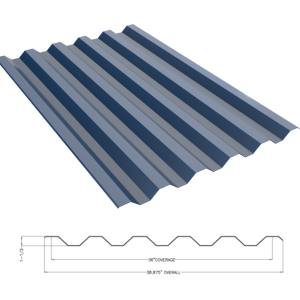

7/8 Exposed Fastener Corrugate Panel

Exposed fasteners are a popular option as these provide your metallic roof with a classic and rustic look. Moreover, these are less expensive as the installation is easier and faster. Corrugated panels have been in use for centuries and can withstand even the strongest winds and storms. Exposed fastener roofing systems require less hardware and accessories, there is no need for additional clips, less trim, or flashing. Corrugated metal panels use a repeating U-shaped wave or corrugation pattern in their design, and are widely known to provide exceptional structural stability.

RPBR Exposed Fastener Corrugate Panel

R panel roofing is a metal roof made of 36” metal panels that have raised ribs and a flat area in between. The panels are used in residential and commercial roofing applications, and can also be used as siding. R panels come in different gauges, ranging from 22 to 29 gauge, but 26 gauge is the most commonly used thickness. These are one of the most cost-effective panels, and are best suited for the constructions where budge is more important than appearance.